Product Introduction

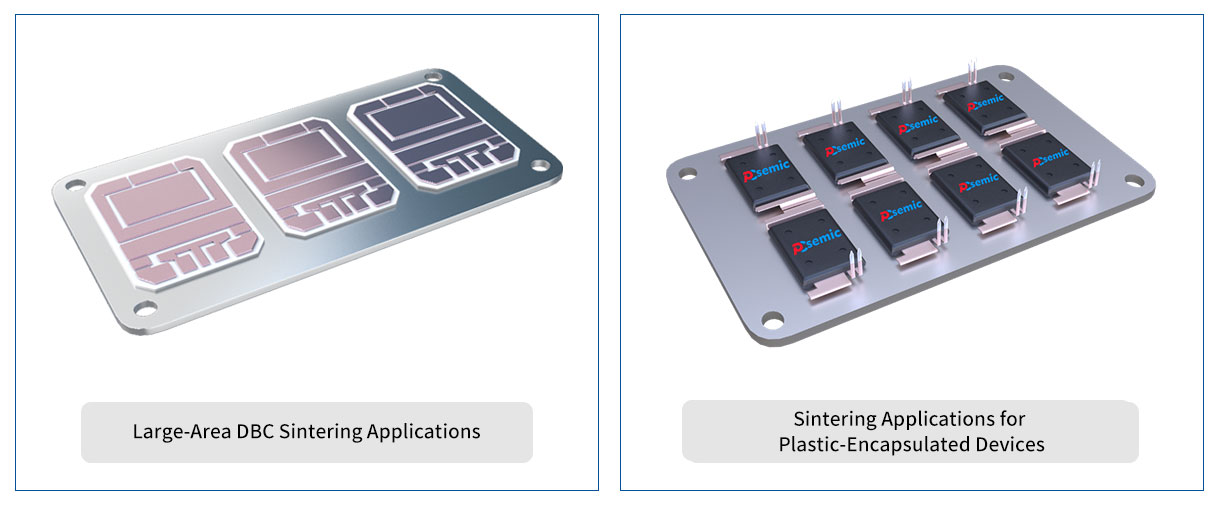

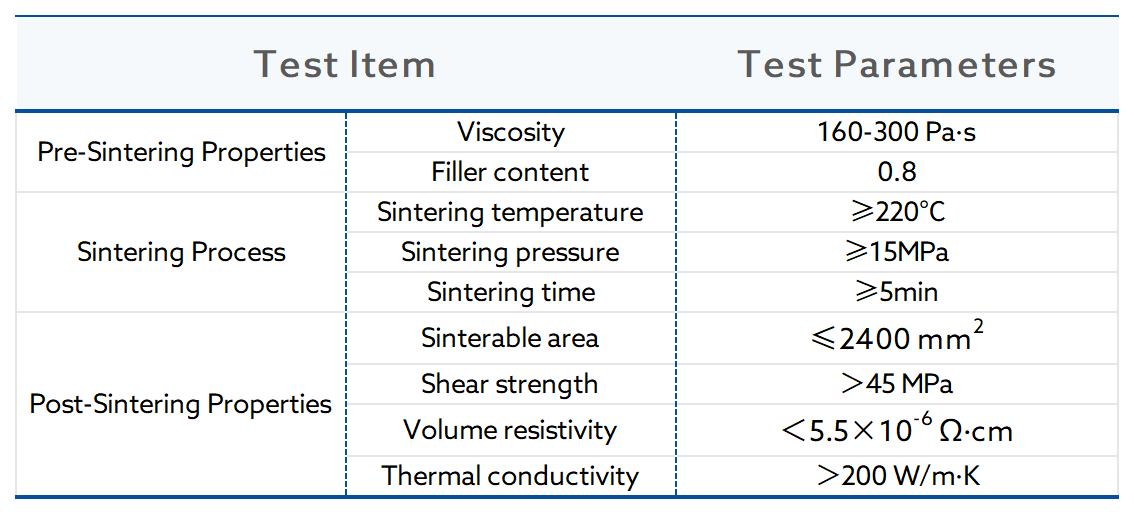

This product is a large area sintered copper paste that assisted pressure (seCure-BC0323) , developed to meet the needs of connecting AMB substrates or plastisol devices to heat sinks. seCure-BC0323 can reduce the sintering conditions to 220°C and 15 MPa, providing customers with a highly reliable solution for large area sintering.

With the continuous development of integration, intelligence and miniaturisation of these high-power devices, the power density of the devices is getting higher and higher, resulting in a rapid rise in device junction temperature (>150°C). Although chip-level packages are now using sintering technologies such as silver or copper sintering to improve heat dissipation and reliability of device, system level devices are still not able to meet the high temperature and high reliability requirements. seCure-BC0323 is a material born to solve the problems, aiming at providing significant increase in the system performance of automotive, industrial and new energy applications to meet the demanding requirements of the next generation of module sintering technology.

● Excellent Workmanship

seCure-BC0323 can significantly reduce sintering parameters, avoiding high temperature and pressure damage to AMBs or plastic module, while maintaining excellent thermal conductivity. The surface is free of defects after printing and drying, preventing the degradation of thermal performance due to large pores and other defects. In addition, owing to the unique copper powder synthesis process and solvent system, seCure-BC0323 exhibits a wide process window, and the slurry can be dried and left for 24h without affecting its bonding performance. Therefore, seCure-BC0323 provide a longer operating time.

● Enhancing Cost-effectiveness

The use of seCure-BC0323 reduces the sintering parameters of the device, providing superior heat dissipation and high temperature reliability, which means the production efficiency of the device、 and its reliability are significantly improved. Additionally, the performance of the module can be further improved, which is expected to match the performance of existing modules while using fewer devices. At the same time, excellent connectivity eliminates the need for thick solder layers to ensure device reliability, reducing the use of packaging materials and thus improving cost efficiency.

Main Performance

●Copper Paste Printing Effect

Copper Paste Printing Results (49x46.5mm, 200µm Print Thickness)

Copper Paste Printing Results (49x46.5mm, 200µm Print Thickness)

Printing thickness 200μm, no printing defects.

Flat surface without cracks after drying.

Thickness reduced to 80-100μm after welding is completed.

● Shear Strength

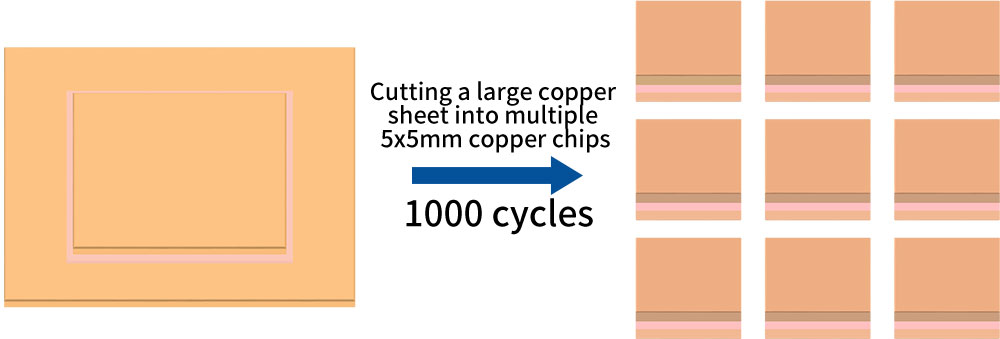

Schematic of large area copper sintering test and shear strength at 230°C and 260°C, with pressure of 15 MPa and sintering for 10 min

Schematic of large area copper sintering test and shear strength at 230°C and 260°C, with pressure of 15 MPa and sintering for 10 min

Due to the large sintered area and high sintered strength, it is not possible to obtain the shear strength of the device directly by pushing the overall structure. We estimate the overall strength of the device by cutting the copper plate into a number of small 5*5mm copper plates, and estimate the overall strength of the device by counting the strength of the small copper plates. Under the sintering conditions of 230℃, 15MPa, and 10min, the sintering strength can reach 48.05MPa, which is still very good under such harsh sintering conditions. When the temperature is raised to 260°C, the sintering strength can be greatly increased to 57.6MPa.

SEM image of sintered body cross-section at 230°C, 15MPa, 10min

SEM image of sintered body cross-section at 230°C, 15MPa, 10min

At 230 °C, the sintered layers are densely connected. The particles are connected to each other and diffuse to form a large sintered neck. This demonstrates the excellent low-temperature sintering performance of seCure-BC0323, which is very suitable for temperature-sensitive devices.

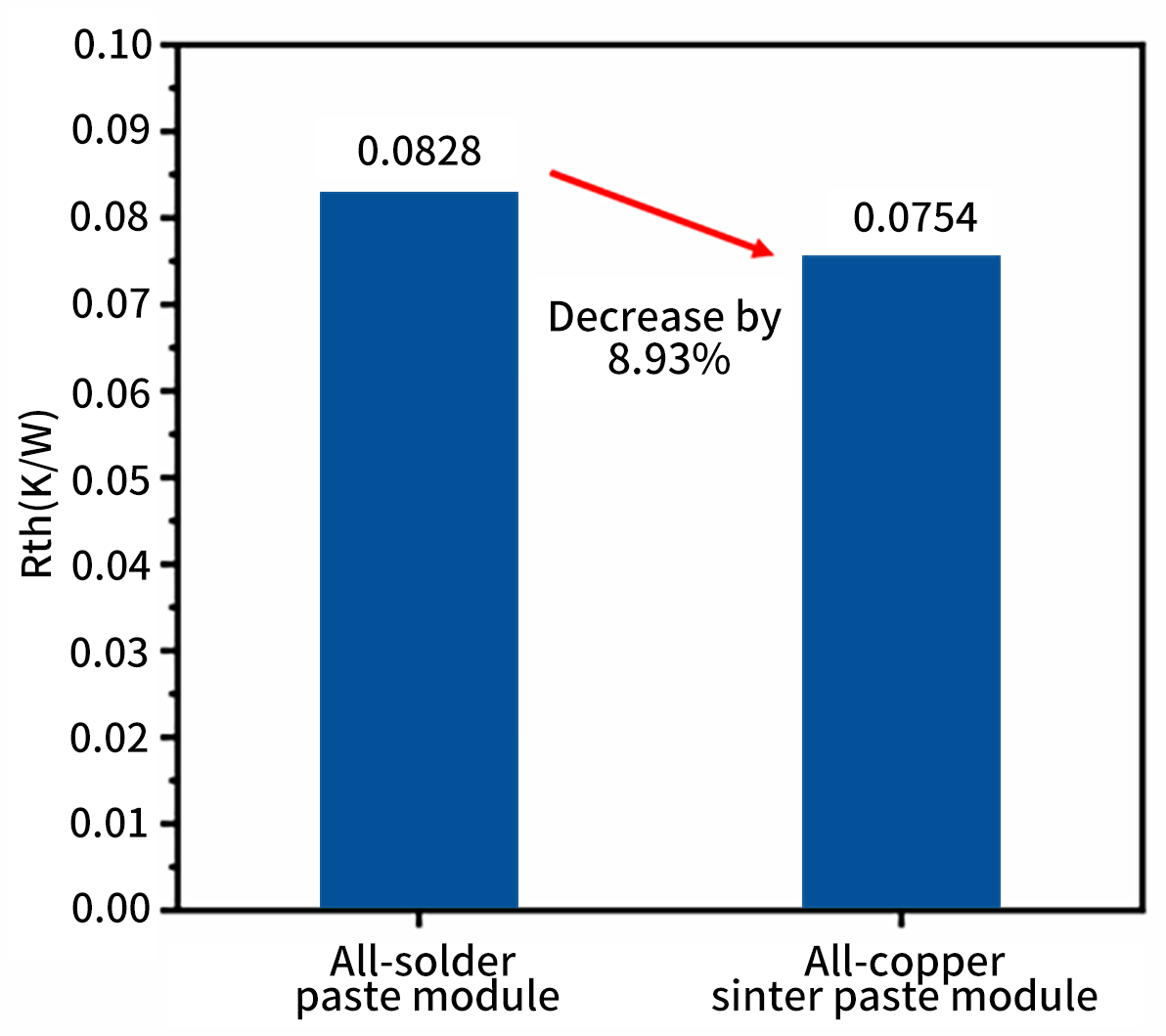

● Shear StrengthThermal Resistance of Device

Thermal Resistance Comparison: All-Solder Paste Module vs. All-Copper Sinter Paste Module

Thermal Resistance Comparison: All-Solder Paste Module vs. All-Copper Sinter Paste Module

All-copper encapsulated modules (the chip is sintered with copper, and the base plate is also sintered with copper) have an overall crust thermal resistance 8.93% lower than that of solder-paste soldered modules. Reducing the thermal resistance of the module can significantly improve the module's heat dissipation effect, ensuring that the device can maintain a lower operating temperature during prolonged high-load operation. By constructing a thermal simulation model, the SiC is set to have a power loss of 80W and a diode loss of 12W, which makes the maximum junction temperature under the full solder paste process close to 150℃. When the lower part of the chip adopts the copper sintering process, while the lower part of the DBC connected to the substrate still adopts the tin solder, the maximum junction temperature Tjmax can be reduced from 148°C to 140.9°C, a decrease of 7.1°C. When the package material of the lower part of the DBC is replaced with sintered copper, the Tjmax can be reduced to 134.9℃. The reduction in junction temperature fluctuation significantly improves device lifetime and increases the device power rating.

Hermal simulation results of the module:

(a) for the chip and the lower part of the DBC with solder paste

(b) for the lower part of the chip with sintered copper and the lower part of the DBC with solder paste

(c) for the chip and the lower side of the DBC with sintered copper

● Reliability

SAT Characterization of the Lower DBC Solder Layer Before and After Thermal Shock Testing

SAT Characterization of the Lower DBC Solder Layer Before and After Thermal Shock Testing

The sintered copper pastes not only have high sintering strength and wide process window, but also have excellent reliability. After 1000 cycles of -55-150°C temperature shock, the device did not show any obvious delamination or large voids, which demonstrates the excellent reliability of the copper solder layer. What’s more, the addition of the copper solder layer can improve the overall high temperature resistance of the device.

Technical

Advantage

● Specifically designed for large-area sintering

● Wide process window and excellent workability

● Lower sintering parameters combined with higher bonding strength

● Capable of withstanding harsher operating temperatures

● Flux-free formulation offers potential for device cost reduction