Product Introduction

seCure-BC1113 Pressure Sintered Copper Paste is developed by Chongqing Pingchuang Institute of Semiconductors Co, Ltd. (PCsemic) , which can realize chip-level low-temperature sintered interconnections and improve the heat dissipation capability and reliability of devices. The product can meet the demand of "low temperature sintering, high temperature service", which can realize high temperature and high reliability operation of power devices.

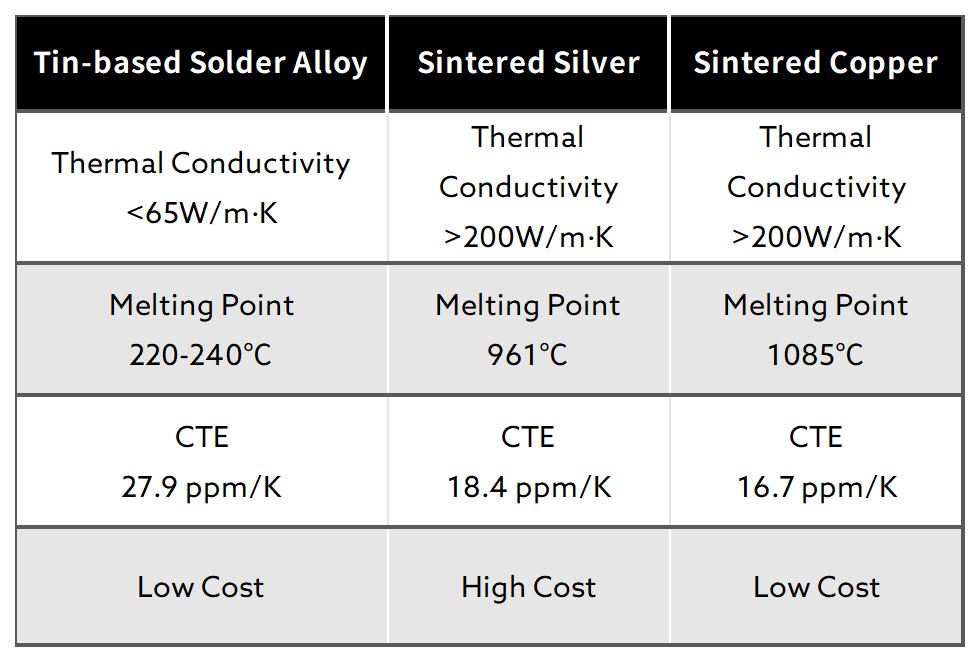

With the continuous development of power device integration, intelligence and miniaturization, the power density of power devices is getting higher and higher. As the representative of the third generation of semiconductor, Silicon carbide (SiC) and gallium nitride (GaN) devices operating junction temperature has exceeded 150 ℃. However, traditional lead-free alloy solder has been unable to satisfy the device heat dissipation and reliability requirements. At present, sintered silver material is mainly used to replace the solder, because the metal silver possess high melting point and high thermal conductivity. Its thermal conductivity can reach more than 200 W/mK, which is 3-5 times the solder paste. Nevertheless, the high price of sintered silver makes the application expensive. What’s more, sintered silver suffers from sulfation and electromigration, which limits its further development.

Copper materials also exhibit excellent electrical and thermal conductivity, while at a tenth of the cost of silver. However, melting point of copper is higher than silver, so smaller particle sizes of copper powder are required to increase the driving force for sintering. At the same time, smaller copper particles mean the risk of oxidation increases exponentially. Oxidation leads to increased sintering temperatures and longer sintering times, causing problems for practical applications of copper sintering.

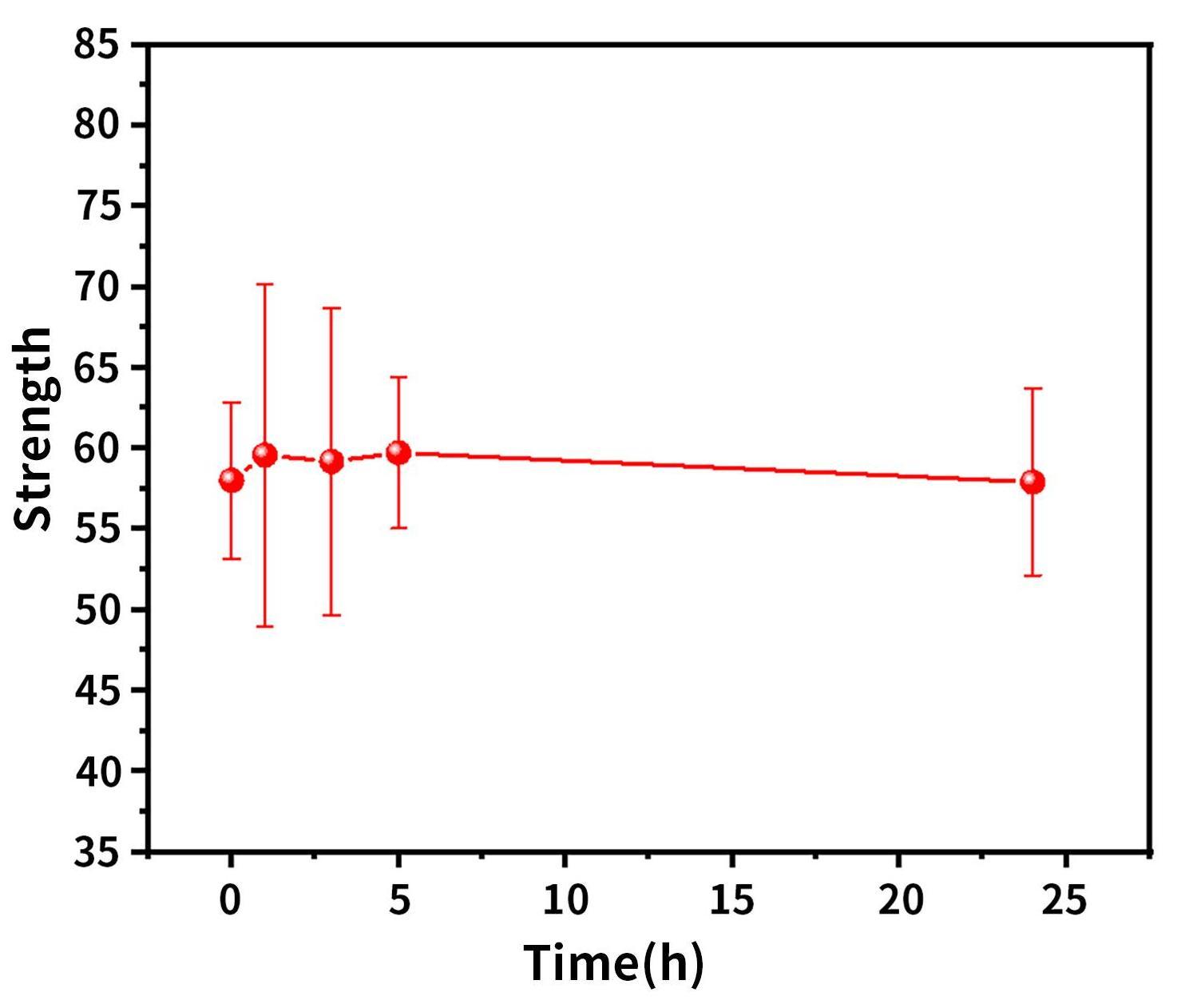

Aiming at the above problems, PC semic has broken through the innovation of antioxidant treatment process of copper powder and the innovation of slurry system, which successfully developed seCure-BC1113 chip-level pressure sintered copper paste. The product owns high antioxidant properties, a long process window, and its sintering performance is not affected even after the copper paste is dried and left for 24h. Its sintering process can be completely consistent with nano-silver sintering, and the shear strength can reach the same levels as that of sintered silver.

Figure 1 Comparison of important indicators of tin-based alloy solder, sintered silver and sintered copper

Figure 1 Comparison of important indicators of tin-based alloy solder, sintered silver and sintered copper

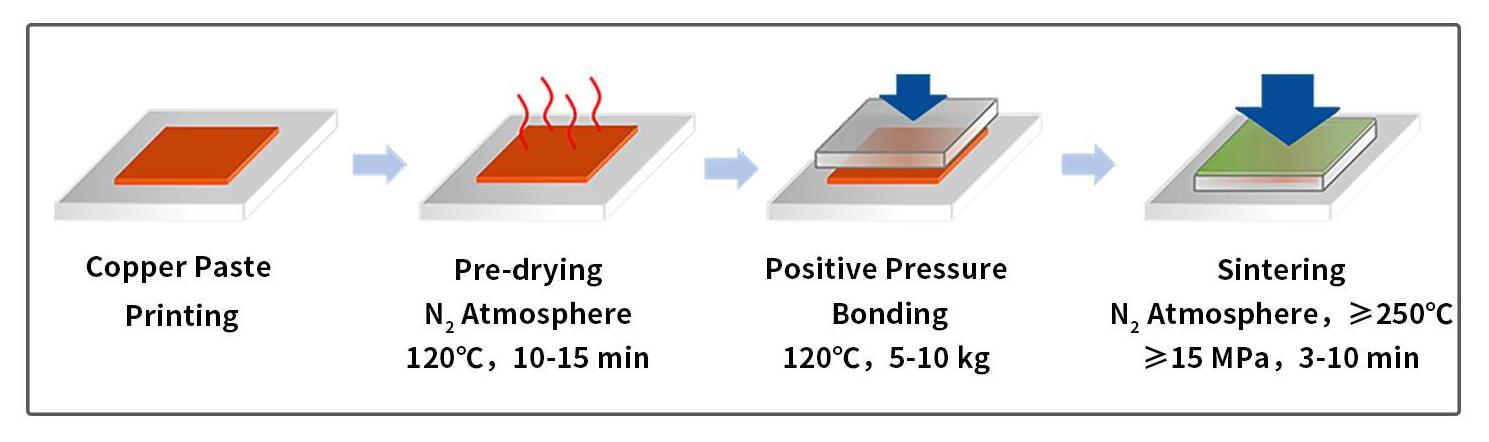

Figure 2 Diagram for sintered copper process

Figure 2 Diagram for sintered copper process

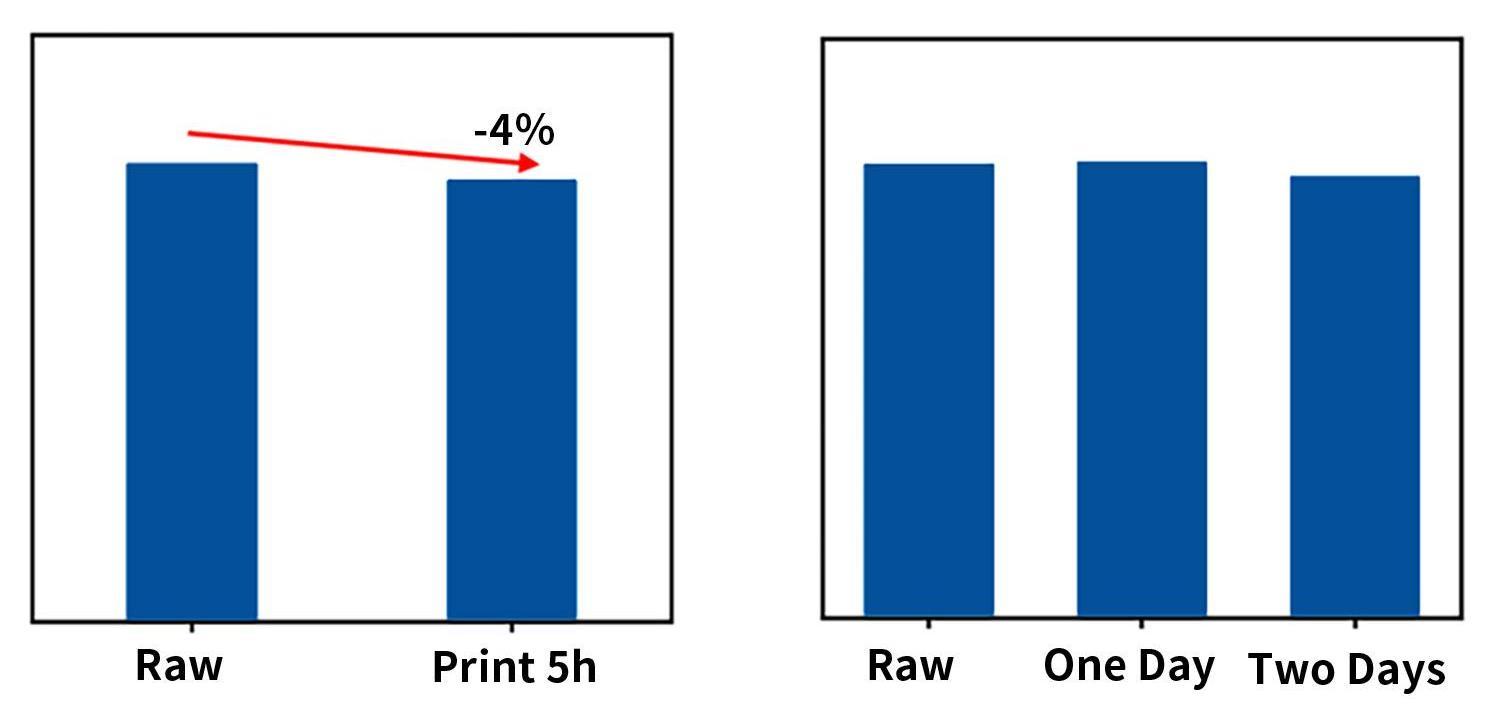

In the continuous printing process, the consistency of paste viscosity is a prerequisite for printing consistency and flatness. Continuous printing test results show that the viscosity of seCure-BC1113 chip-level pressure sintered copper paste only changes by 4% after 5 hours of continuous printing. In addition, the unique paste system supports the copper paste to be placed at room temperature for 3 days and re-homogenized with almost no change in viscosity, which broadens the process window of copper paste. What’s more, the slurry can be dried for 1h, 3h, 5h and 24h without affecting its strength, thus providing a longer operating time.

Figure 3 Viscosity change of sintered copper in continuous printing and at room temperature

Figure 3 Viscosity change of sintered copper in continuous printing and at room temperature

Figure 4 Shear Strength of sintered copper after drying for different periods of time

Figure 4 Shear Strength of sintered copper after drying for different periods of time

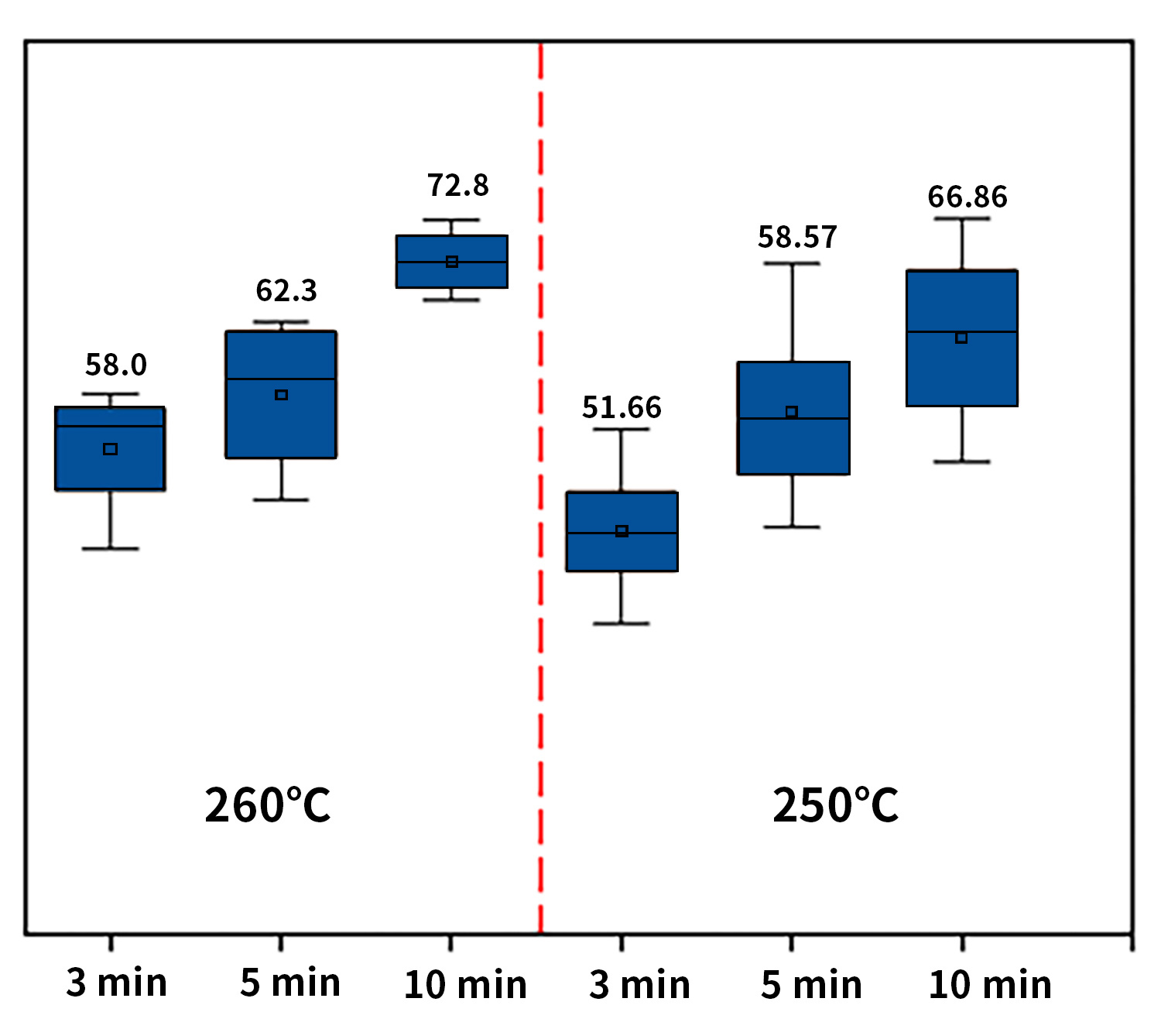

Based on Boschman sintering equipment, SiC chips (5 mm*5 mm) were sintered using seCure-BC1113 pressurie sintered copper paste under nitrogen environment at 250°C or 260°C, and 20MPa pressure for 3min, 5min, and 10min, respectively. The shear strength results show that even at 3min sintering time, the shear strength of sintered copper is still >50MPa, achieving the same sintering effect as that of sintered silver. The shear strength gradually increased with the extension of time. From the process steps to the equipment conditions, sintered copper can be used as a low-cost alternative to sintered silver without additional requirements on the customer's production line.

Figure 5 Sintering parameters and sintering effect data for sintered copper at 250°C and 260°C under 20MPa pressure

Figure 5 Sintering parameters and sintering effect data for sintered copper at 250°C and 260°C under 20MPa pressure

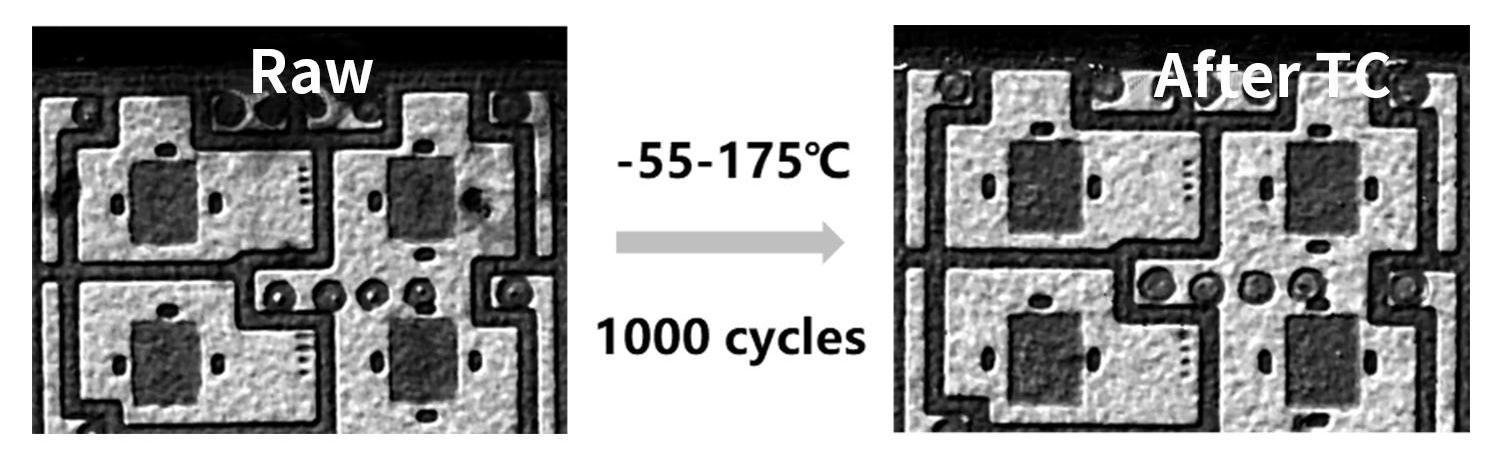

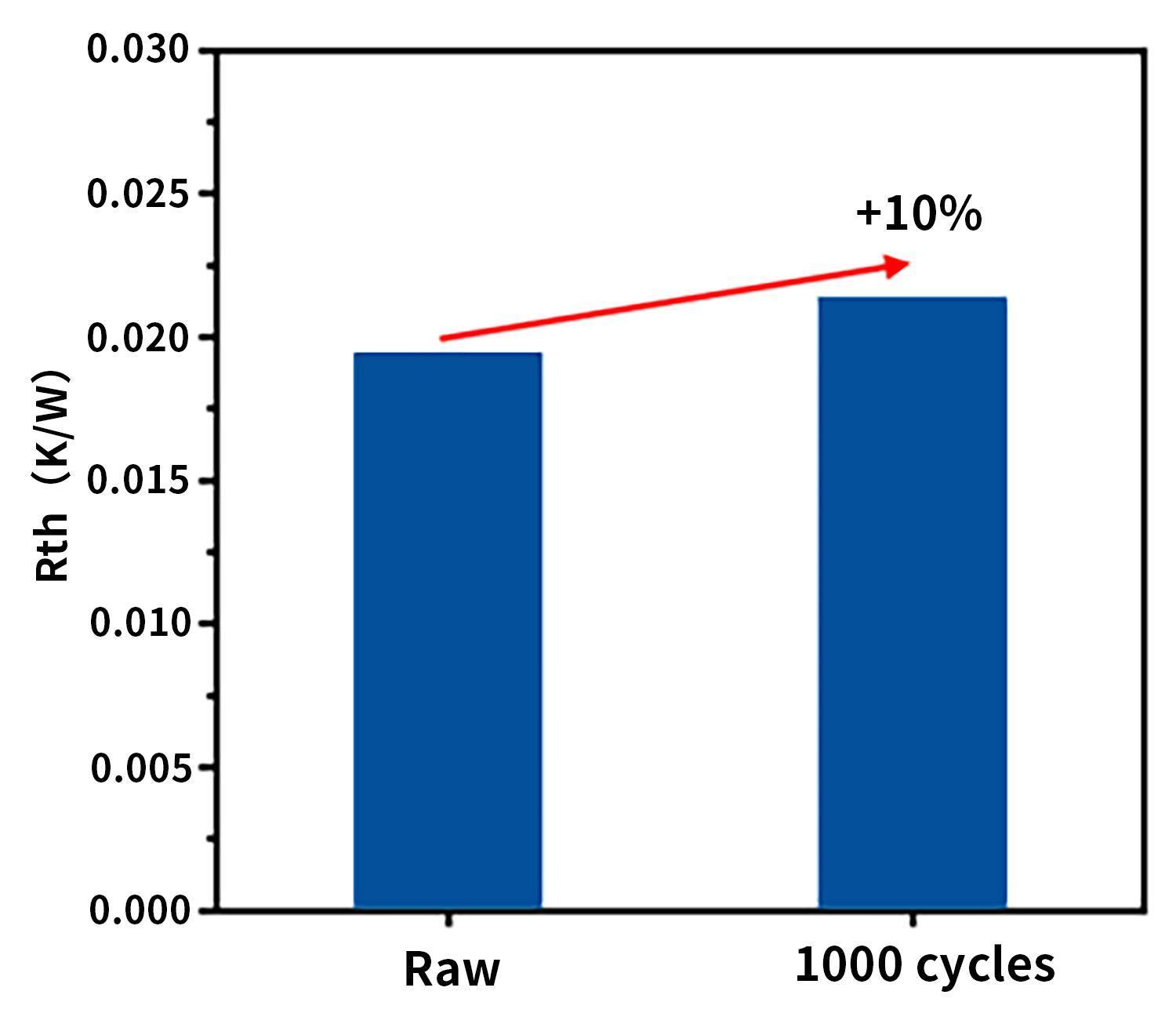

The publication of seCure-BC1113 chip-level pressure sintered copper paste not only possess high shear strength and wide process window, but also has excellent reliability. The sintered copper encapsulated device supports the highest temperature thermal shock test of -55-175°C. As shown in Figure 6, after 1000 cycles of thermal shock test, the solder layer of the chip has not been delaminated, which proves that the sintered copper layer has excellent reliability. Under the extreme thermal shock conditions, the thermal resistance of the device solder layer increases by only 10%, which meets the reliability test index.

Figure 6 SAT characterization of solder layers before and after thermal shock test

Figure 6 SAT characterization of solder layers before and after thermal shock test

Figure 7 Thermal resistance of solder layer before and after thermal shock test

Figure 7 Thermal resistance of solder layer before and after thermal shock test

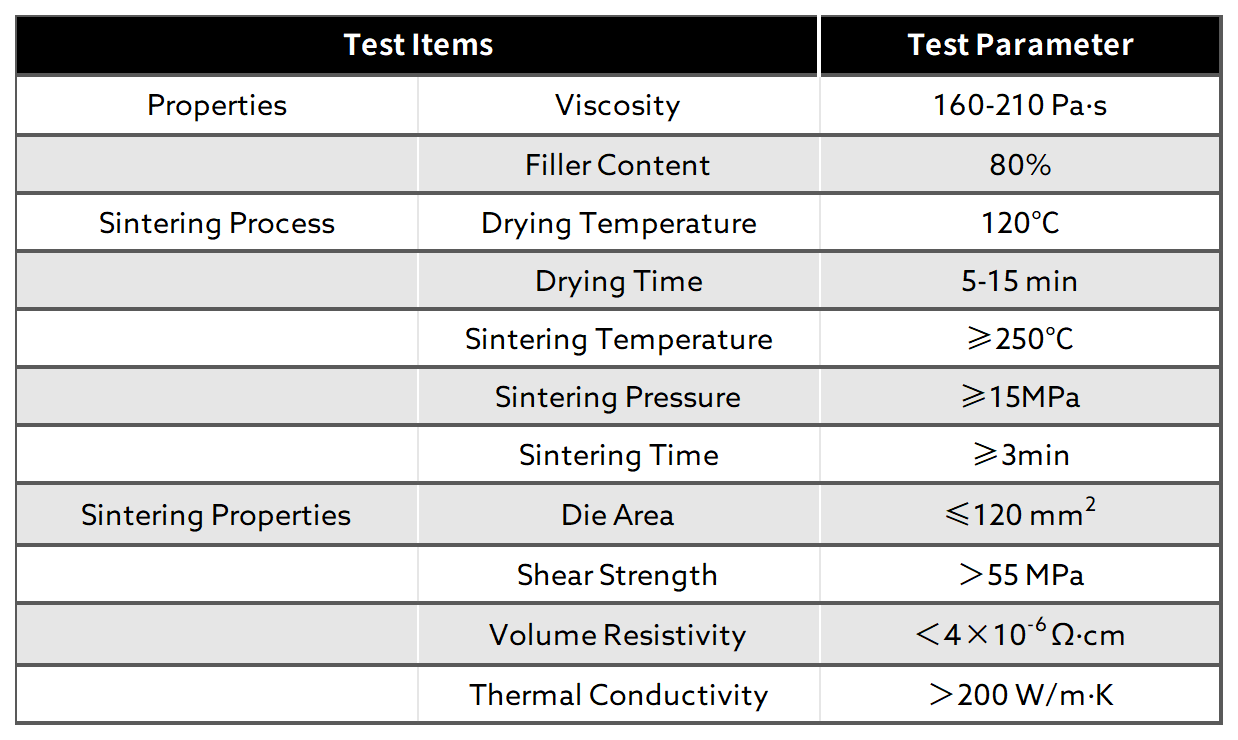

Technical Parameters

Product Advantages

- Perfectly matches SiC device service requirements

- No flux cleaning, no spattering problems

- Over 1000°C service temperature

- Reduced thermal resistance and improved reliability

- Compatible with Cu, Ag and Au plated surfaces

- Perfectly adapted to existing production line

Contact Information

If you are interested in our products, please feel free to contact us!

Sales Manager: Mr. Wang 13678423140

E-mail: semicsales@pcsemic.com